Processes

There are seven manufacturing processes that we consider important in our company in order to obtain the best result in product processing and to be able to meet the expectations of our customers:

storage of raw materials, sheet metal cutting, bending, steelwork assembly, machining, sandblasting and painting.

Storage of raw materials

All the raw materials used for the construction of the products are stored in special cantilevers, divided by type and identified with special forms in order to guarantee the traceability of the material.

Sheet metal cutting

The sheet metal cutting is made on laser machines with automatic loading and unloading and high precision oxy-cutting machines.

Bending

The bending of the sheets is carried out on bending machines of different sizes and tonnage that allow to bend a thickness of 15 mm and a width of 2000 mm.

Assembling and Welding

For the assembling phases are used a special equipments built for the customer, for welding there are qualified operators

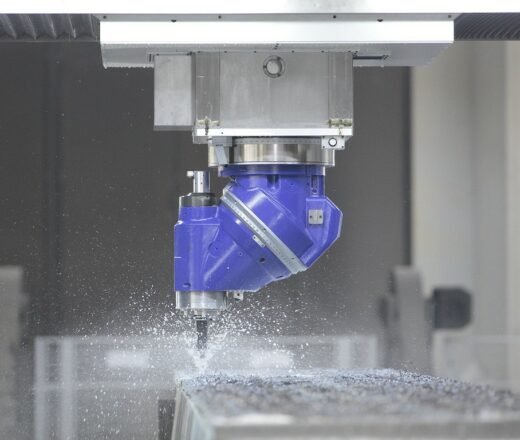

Machining

The available machines are mobile column milling machines or portal milling machines until a lenght of 30 meters.

Sandblasting

Sandblasting is a mechanical process by which the most superficial part of the material is eroded by abrasion, with a jet of metal spheres and corundum. Nuova Faos has 2 sandblasting plants with total recovery of dimensions Width 5 M, Height 5 M and Length 15 M.

Painting

On customers’ request, we have the possibility to paint the produced pieces with the desired RAL. We have grouting and painting booths and a drying furnace.

Contact

Via Case Nuove 245/A CAP 47842 San Giovanni in Marignano(RN)

Telephone 0039 0541 825500

Privacy policy - Cookie policy - Whistleblowing - Data protection policy G.D.P.R. UE 2016/679